Technology

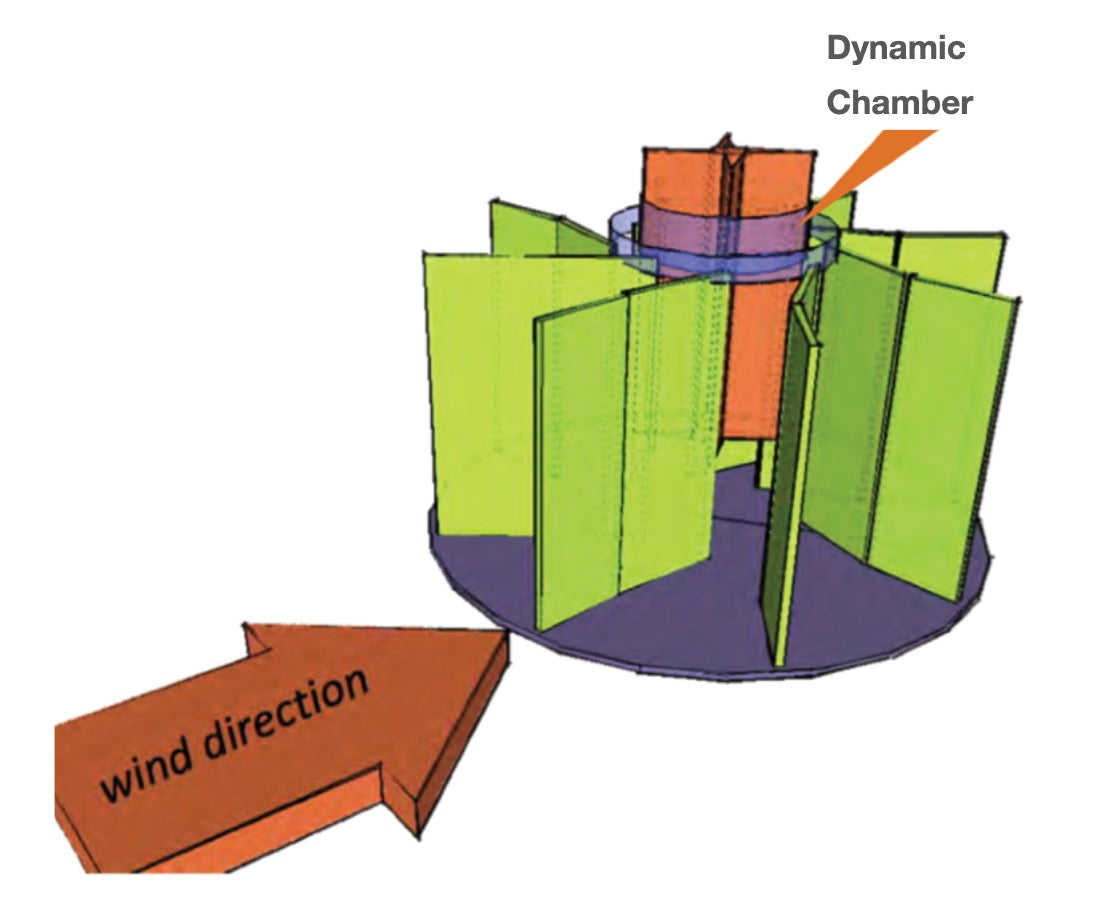

CBC's innovative technology is based upon stationary enclosure that intercepts and concentrates wind in a dynamic chamber, which in turn focuses and directs the wind towards a solid 4-point rotor in the center. This technology is covered by US Patent 10,495,063.

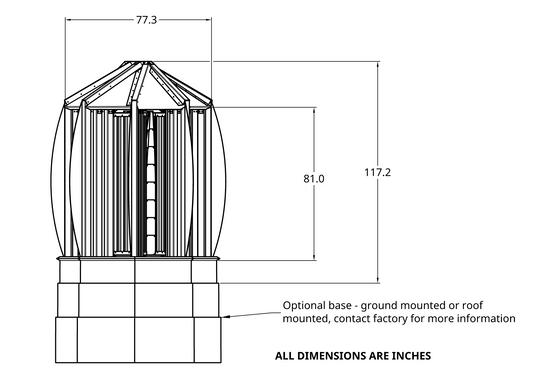

The enclosure is a Category 5 hurricane-resistant structure which houses and supports the rotor. Since it is stationary, the structure can be mounted on the roof of a building. Such a structure lends itself to a product life commensurate with the life span of the building / structure to which it will be mounted. Its appearance can be adapted to 'hide' the system in plain sight. There is no need to point the equipment into the wind. The CBC WES are omni-directional, meaning they can collect wind from all directions.

Since the technology is a stationary mechanical structure, it is analogous to other roof top mounted building systems equipment such as HVAC systems, commercial utility structures, and water tanks for instance. In the absence of a building on which to mount the equipment (or if preferred), the equipment is fully capable and compatible with ground mounting and tower mounting. (A compatible tower would be an appropriately sized platform lattice tower, similar to a fire tower)

We are the only flight-ops compatible wind energy technology

DAF can easily install systems on buildings, air fields, vehicles, and forward deployed locations as a grid and fuel alternative with no risk to low flying aircraft.

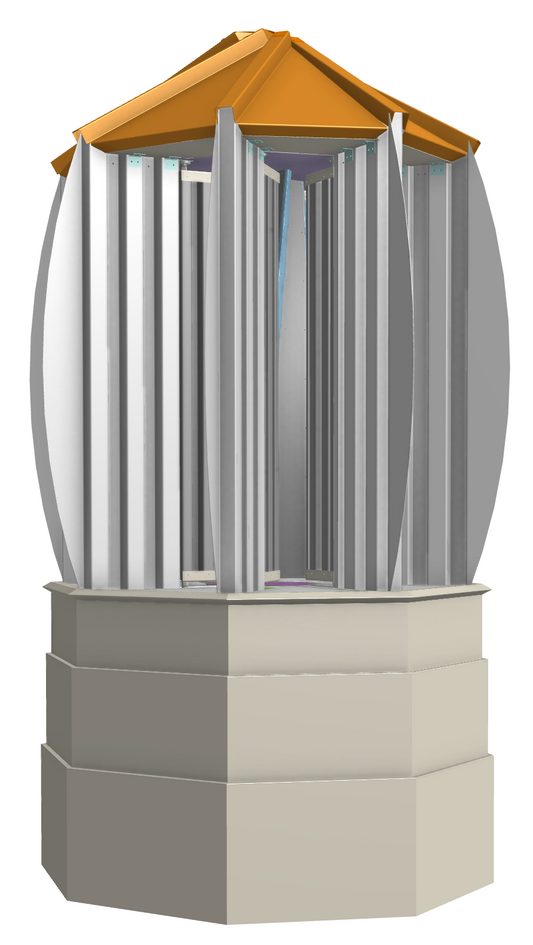

Wind Concentrating Enclosure

The keystone element of the system is its stationary wind concentrating enclosure. It intercepts a greater amount of wind energy without increasing the size of the blades. It collects wind from all directions without having to be pointed into the wind. CBC's unique design includes a stationary wind concentrating enclosure that provides distinct and unique benefits:

Allows equipment to be roof mounted.

Allows the equipment to be 'hidden in plain sight', either blended into an existing building or disguised as a light-house, Silo, Watchtower, or Cupola.

Multi-directional: collects wind from all directions.

Concentrates wind: turbine reaches full power in low wind speeds.

Stationary structure

- Friendly to birds and other wildlife

- Results in zero shadow flicker

- Structure can be incorporated and 'hidden' into existing building.

- Stators can be used as signage in appropriate locations.

Quantum leap in wind tech results in unparalleled performance

A Look Inside

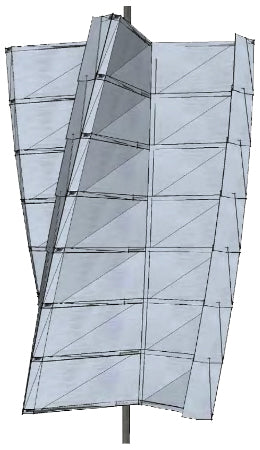

At the center of the enclosure is a dynamic chamber which changes size and shape in response to changes in windspeed and direction, optimizing airflow around the rotor. The sails forming the chamber are mechanically controlled using calibrated springs to provide a highly fault tolerant and reliable system. It is helpful to visualize the way in which a potter forms clay on a potter’s wheel, which is similar to the way in which the sails of the enclosure form the wind into a vortex around the rotor.

Next Generation Rotor

Light-Weight, High Performance, And Supported From Top And Bottom For Unparalleled Stability

Dynamic Shaping

Chambered Enclosure Dynamically Changes Size And Shape In Response To Ambient Wind Speed And Directional Changes

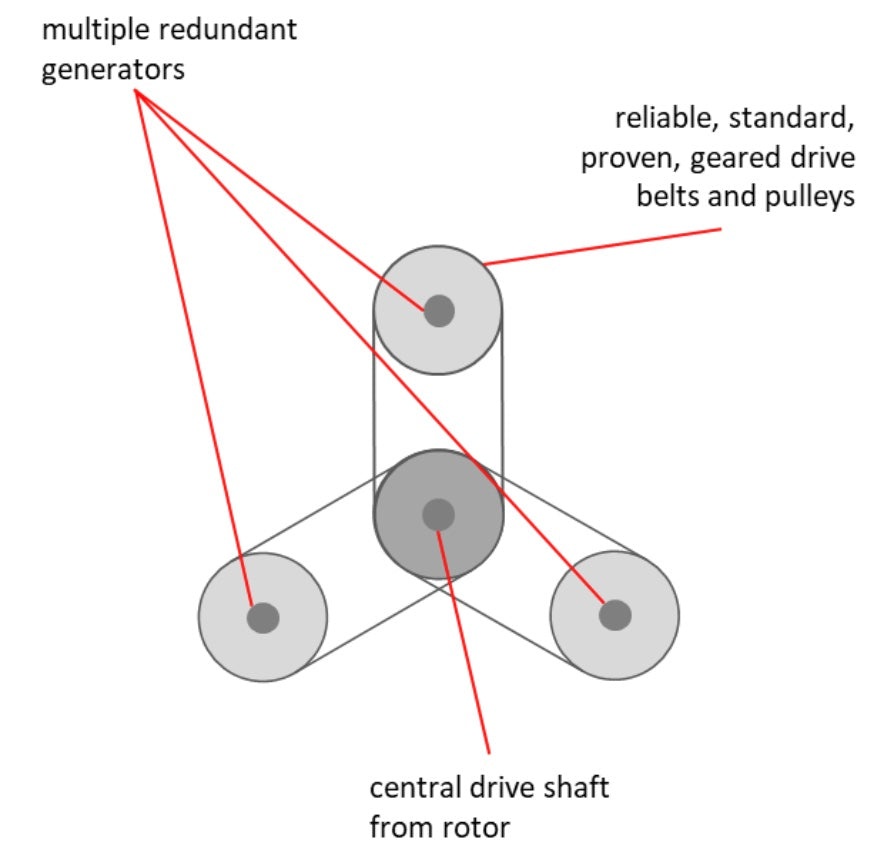

Multiple Generators

Single Rotor Drives Redundant Generator Systems Ensuring Power Is Always Being Produced

Variable Load Generator Array (VLGA) Ensures Staggered Generator Startups Providing Optimizes Conversion of Available Wind

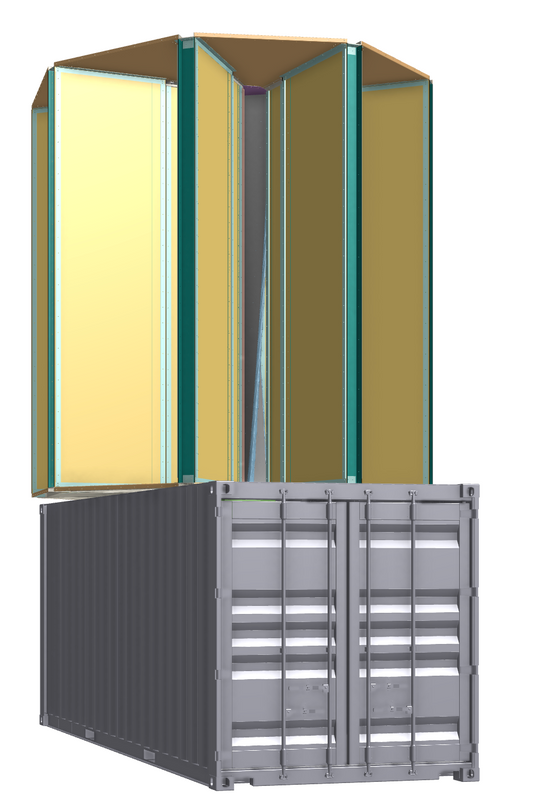

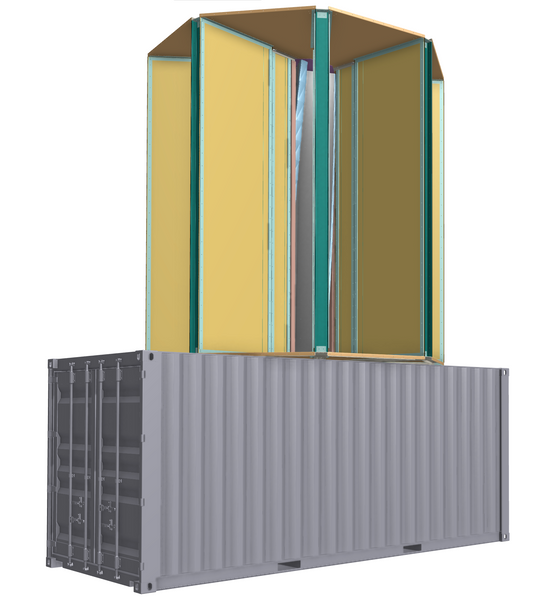

HIPS Wind Energy Systems

-

Crisis Response Series (CR Series)

Vendor:CBC Wind EnergyRegular price $30,000.00 USDRegular priceUnit price / per -

Cupola Series (CP Series)

Vendor:CBC Wind EnergyRegular price From $6,000.00 USDRegular priceUnit price / per